A new product line for self regulating heating cables is in service since September 2014 enabling us to our enlarge our production capacity, now at 3000m a day. The semiconductor is thus set form on its two energy bus wires, the isolation jacket is extruded, samples are taken automatically and regularly at random to carry through conformity checks, the printing and the conditioning of reel are all performed without any interruption on the product line.

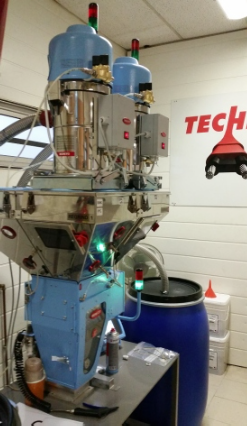

For the preperation of our semi conductor mixtures a new automised dosage line has seen the light to homogeneit the quality of our self regulating heating cables.

TECHNITRACE braiding capacity in tinned copper and stainless steel has been reinforced by the installation of a new high speed braider (SPIRKA) .