Project Description

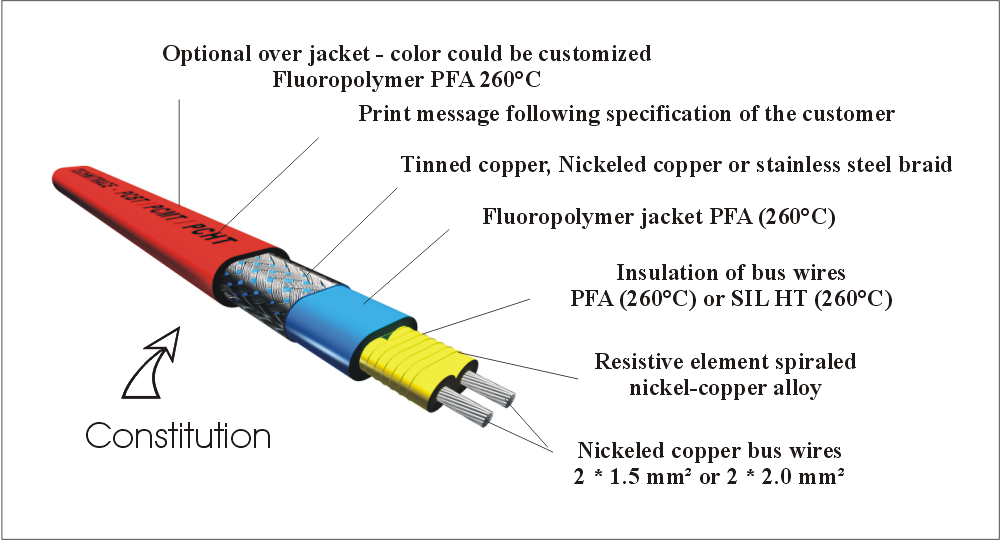

The constant heating cables PCHT consist of heating zones that dissipate a constant heating power whatever the environment temperature. Constant wattage heating cables PCHT can be cut to lenght on the heat tracing site, they allow connecting branches from a single point of electrical power supply (power along the whole cable lenght) and are mainly dedicated to the following surface heating applications :

APPLICATIONS RANGE

- Freeze protection of liquid-food pipes withstanding high pressure steam rincing.

- Temperature maintenance of pipes, tanks and reservoirs up to 120 ° C.

- Pre-heating and anti-condensing of hoppers, filters, heavy fuel oil lines.

- Pre-heating of loading/off-loading lines or of bituminous products.

- Temperature maintenance in chemical and industrial environments.

MAIN BENEFITS

- Withstand superheated water sterilization or high pressure vapour sterilization

- No thermal ageing of heating resistance wire (alloy)

- No peak inrush current enabling a good electrical protection

- Constant wattage heating cables PCHT are build-in cold connection due to the manufacturing design

- Cut to the requested length on-site

- Fluoropolymer insulation resistant to acids, bases and most chemical products

- Temperature class 260°C

- Allow connecting branches from a single point of electrical power supply (power delivred all along the whole cable length)

- Very easy to implement

- Standard voltage 230 V and 400 V

- Optional specific voltage 24 V to 1500 V (contact us)

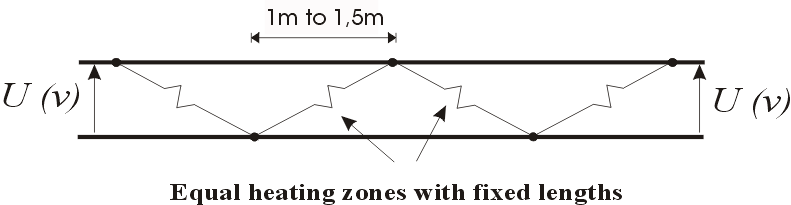

OPERATIONAL PRINCIPLE

MAIN FEATURE

- Maximum length : 110 m or 1500 W

- Maximum exposure temperature power off : 260 °C

- Maximum exposure temperature power on : according to power output :

- PCHT 10 W/m = 150°C, PCHT 20 W/m = 130°C, PCHT 30 W/m = 120°C

- Thermal protection : rated current * 1.25

- Compulsory residual-current circuit breaker : 30 mA

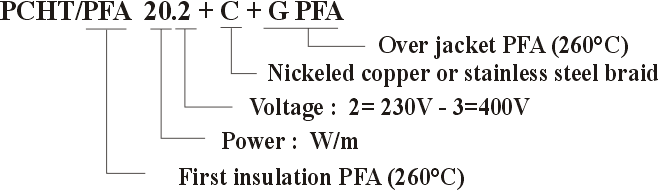

PRODUCT CODE