Project Description

CAMT medium temperature self-regulating heating cable consist of a heating semiconductor plastic element which adapts its calorific power (W/m) on each point depending on the local temperature. This intrinsic feature of the semiconductor heating element allows in some cases to dispense of using a thermostatic controler (self-regulation).

They can be cut on the adjusted length directly on the job site. For your heat tracing installations and especially on temperature maintenance of hot water

systems, we strongly recommend the combination of our electronic THS / E controllers with a Pt1000 sensor to apply directly on the pipe. The latter are equipped with a current absorber for start up of self regulating heating cables. They are the guarantee of a rigorous and reliable electronics regulation (energy saving of + 50%). The fluoropolymer insulation is the gaurantee of e perfect thermal and chemical resistance.

OUR RANGE OF APPLICATIONS

Self regulating trace heating cables CAMT for

- Temperature maintenance of hot watter pipes at 45/50/55°C

- Temperature maintenance of hot watter pipes at 60/65°C

- Temperature maintenance of pipes, vessels, baloons until 75°C

Do not use the CAMT heating cable on plastic pipe.

It is imperative to comply with FIQ93 operating instructions.

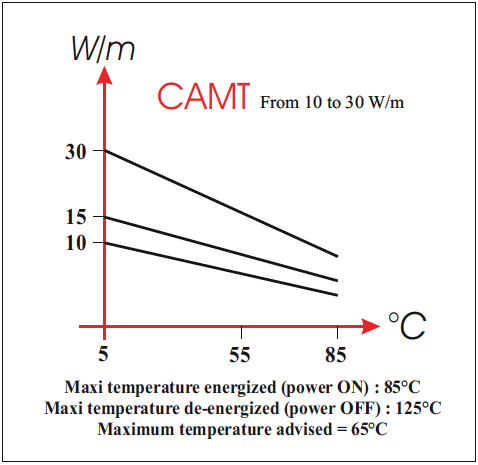

Warranty maxi exposure temperature : power ON = 85°C / power OFF 125°C.

Maximum maintenance advised temperature : 65°C.

Beyond these exposure temperatures use control thermostat.

MAIN BENEFITS

- can be cut directly on the adjusted length on the site

- allow derivation from a unique and single feed point

- semiconductor heating element adapts its power locally

- good flexibility allowing the tracing of hydraulic organs (valves, pumps, …)

- allow overlaps during implementation (self-regulating)

- maxi temp energized : 85 ° C (power on)- maxitemp de-energized : 125°C

- Technical CSTB approval, in accordance with the European standards in force

MAIN FEATURES

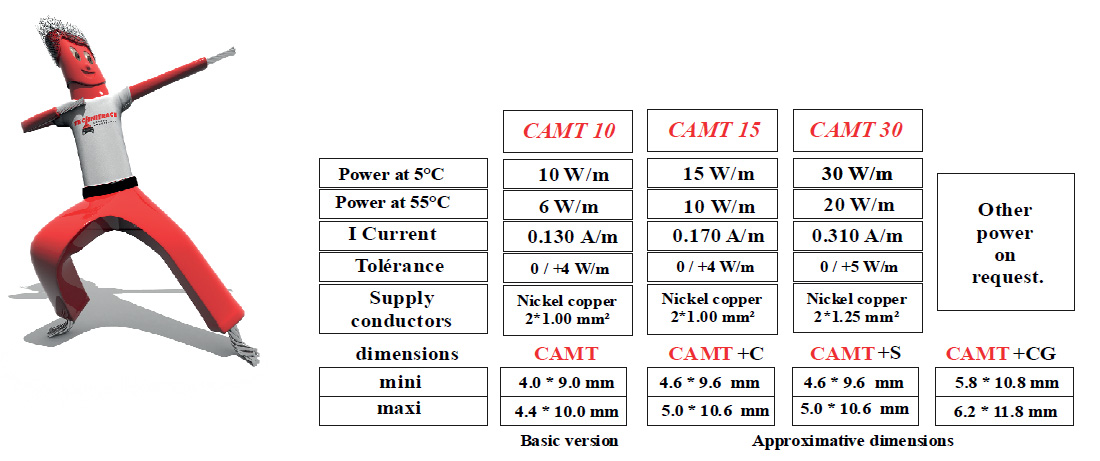

The diffusion of heat generated by our self regulating heating cable varies and depends on where the cable is situated and the cables contat temperature.

Thermal power output determined by the manufacturer in compliance to standard EN62.395

Thermal dissipation curves are theoretical and given for information purposes

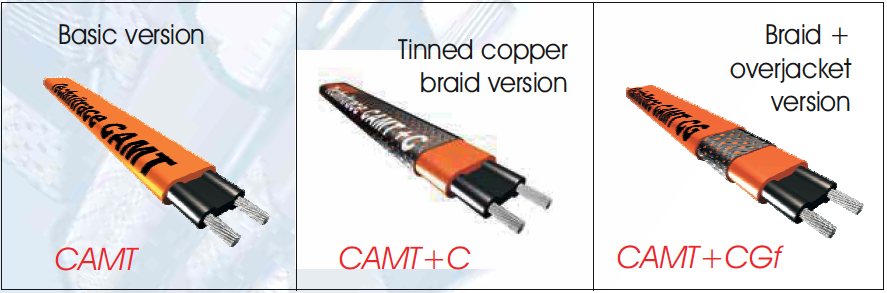

- FEPfluoropolymer jacket

- FEP fluoropolymer overjacket (CGf version) for corrosive and chemically aggressive environments

- voltage: 230 V / 240 V / 50 or 60 Hz (115 Voptional)

- thermal calibration: Max. rated current * 2

- use C or D curve circuit breakers

- possibility of a maximum current spike of 3 * In / 300ms

- necessary use differential circuit breaker: 30 mA

- maximum length / power point = approximately 110 m

- maxi temperature exposure : power ON = 85°C

- maxi temperature exposure : power OFF = 125°C

ACCESSORIES